Posted: Jun 14 '19

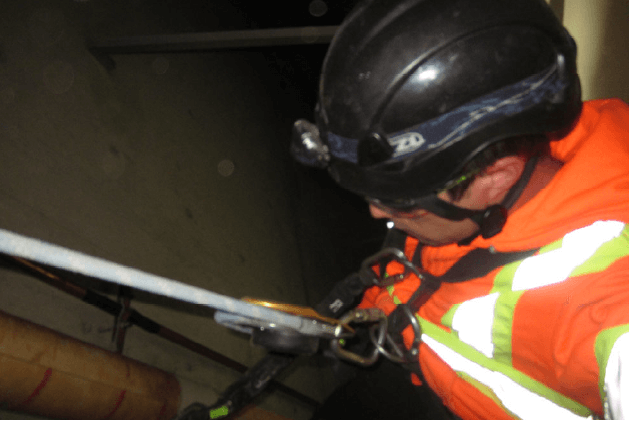

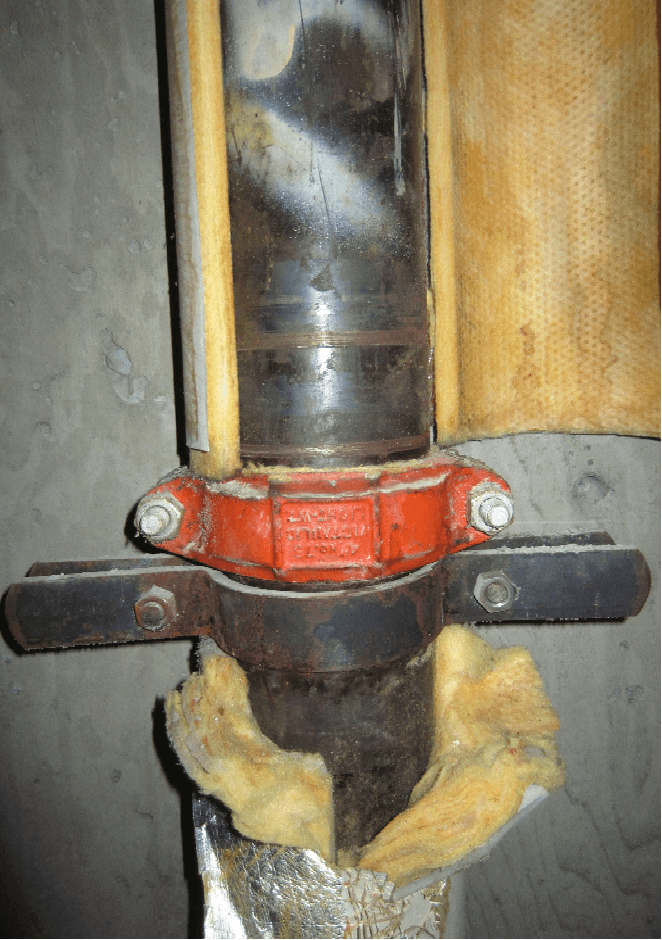

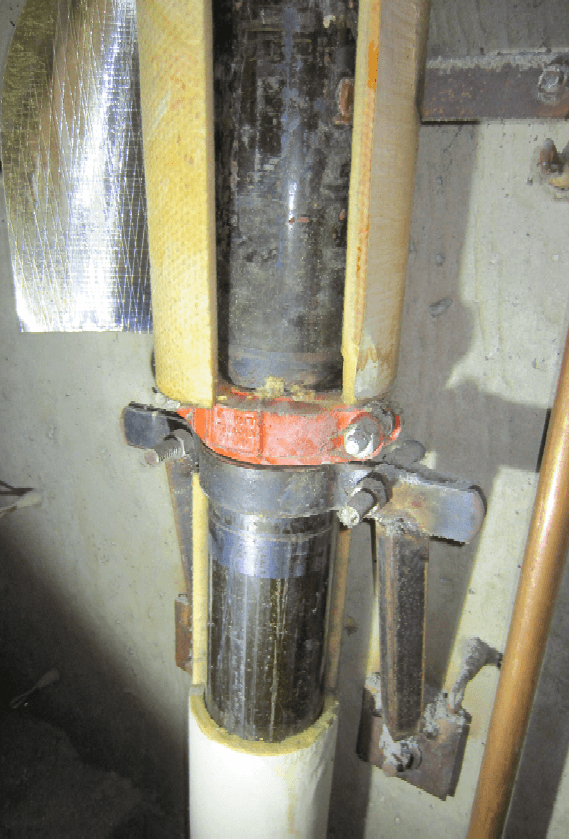

Commercial Building Operator needed leaking pipe repaired that was situated 35’ off the ground level in the ventilations shaft of a 6 story building. The leaking pipe was dripping onto the ceiling of a laboratory. It was not feasible to enter the space from the laboratory, so we had to rappel into the space and fit the leaking pipe off of ropes. We completed this project in 6 hours, and saved the building owner several thousands of dollars using this technique. The other option would have involved setting up scaffolding and shutting the laboratory down for several days.

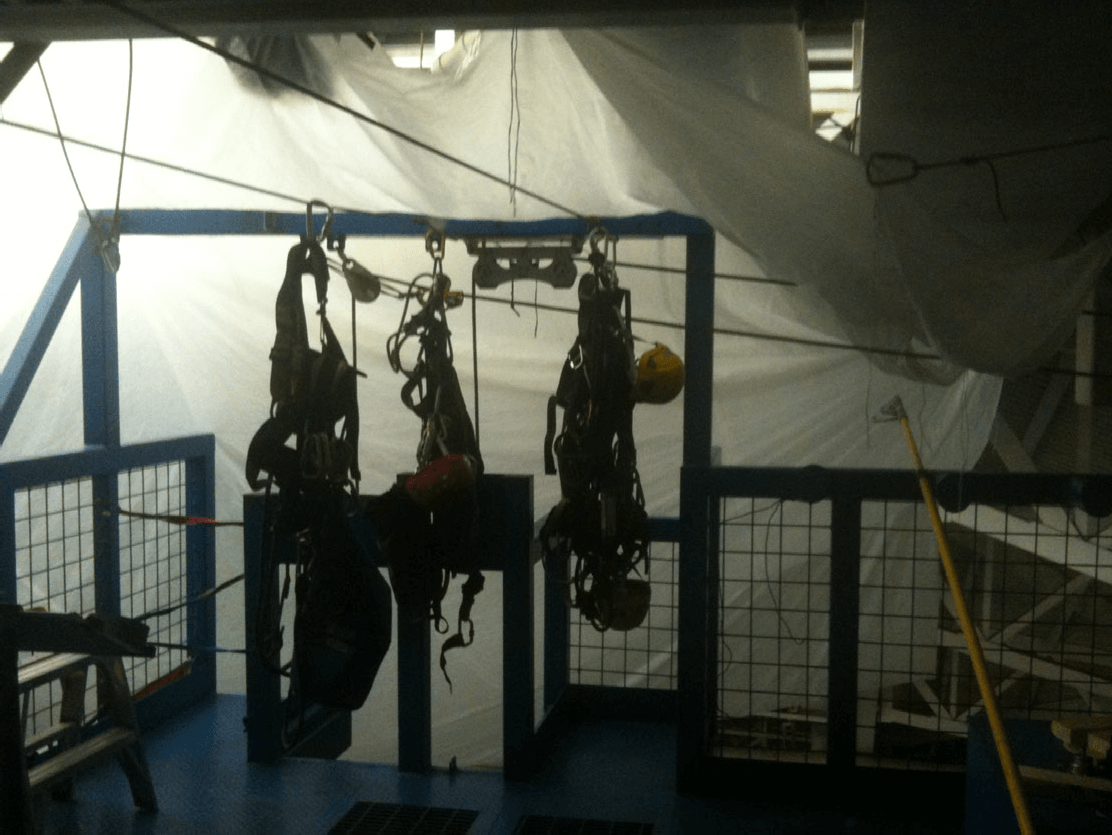

This water park facility required some touch up painting to a section of the roof trusses to guard against corrosion damage. The work area

was located above a wave pool and bungee tower, additionally the facility had to remain in operation during the day. We were able to

successfully place a tarp under the work area, remove corrosion and paint a 100’ x 100’ area of the roof structural members.